-

Hammer Mill Manufacturers Africa | Drotsky

Hammer Mills. A perforated metal screen covers the full circle of the milling chamber and this allows properly sized material to pass as finished product while the course material remains in the milling chamber for further grinding. The screen size determines the finished size of the product.

Get Price -

Hammermills Sudenga Industries, Inc.

Simplicity is the hallmark of this hammermill's design. Varying screen size attains proper particle size and varying motor horsepower ensures the Liberator Series mill fits the capacity needs of the job. Longterm maintenance costs are considerably less expensive than similar capacity roller mills.

Get Price -

Hammer Mill Hammers Columbia Steel Casting Co., Inc.

Primary hammer mills often require manganese steel hammers due to severe impact resistance requirements. Manganese steel hammers are also the choice for customers who rebuild their hammers with manganese weld and/or carbide overlays. Columbia Steel can also supply manganese hammers with factory applied chrome carbide overlay.

Get Price -

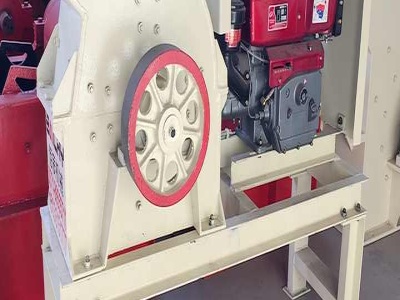

Hammer Mill for Biomass Pellet Plant

Designed on the top of the hammer mill, the feeding hole can be adjusted to meet diversified demands for rotor rotating. Thanks to the creative design, two kinds of sieve clearance can be made, one for preliminary pulverization and the other for refined grind.

Get Price -

hammermilldesignminiproject SlideShare

Apr 12, 2016· The hole fits onto a rod inside the hammer mill and swings to hit the material. The hammer design of hammer mill is determined by operating parameters such as rotor speed, motor horsepower, and open area in the screen. Optimal hammer design and placement will provide maximum contact with the feed ingredient.

Get Price -

Hammermill 4/24/06 9:06 AM Page 1 Hammer Mills

hammer arrangements, and are all supported between durable pillow block bearings. These proprietary design factors combine to provide a controlled, uniform granular grind with the benefits of easy maintenance. Hammer Mills AVAILABLE SIZES CAPACITIES Model Screen Area Sq inches Avg. hp RPM G5 440 5 15 1800 3600 G6 540 15 30 1800 3600 G7 790 40 60 1800 3600

Get Price -

Hammer Mill Design Pdf

design and construction of hammer mill fxtraders. Hammer Mill Crusher Grinder. Improvement on the Design,Construction and Testing of Hammer Mill Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Get Price -

Hammer Mill Soil Grinder | Soil Pulverizer | Rock Crusher ...

Dwell Earth has developed the most productive, yet affordable Hammer Mill Grinder to run and operate. The GME14 Hammer Mill Soil Crusher makes grinding up soil clumps, rocks, and minerals easier than ever before. Learn more about the enhanced features, benefits, and cost of the soil pulverizer machine.

Get Price -

The Steps For Design Of Hammer Mill

The hammer crusher machine can process the raw material with medium hardness in . The structure design of hammer mill crusher is perfect and the resistance to . Get Price And Support Online; Feed Hammer Mill with Large Capacity Fish Feed . Feed hammer mill with waterdrop design can grinder various grains into powder preparing for feed pellets.

Get Price -

Hammer Mill Grinder Classifier Milling Systems

Hammer Mill. Used in an everexpanding variety of applications such as cryogenic grinding of plastics and rubber and cosmetics, CMS's hammer mill grinder is in demand by professionals in the food industry, and is used in manufacturing sugar, herbs and spices, flour, and corn starch. Available in virtually indestructible fabricate...

Get Price -

Hammer Mill Operating Principle

Hammer Mill Crusher. The most important results from the installation of the Dixie (NonClog) Hammermill are the uniform high quality of the product and the enormous crushing power, which, with reduction range of this mill, eliminate the necessity of using several units to obtain the necessary production. The Dixie (NonClog)...

Get Price -

Hammermills Sudenga Industries, Inc.

An integral part of any feed production system is a reliable and low maintenance mill. Simplicity is the hallmark of this hammermill's design. Varying screen size attains proper particle size and varying motor horsepower ensures the Liberator Series mill fits the capacity needs of the job.

Get Price -

Stationary Hammer mill Art's Way Manufacturing Co., Inc.

Lower maintenance costs are an added benefit of the Hammermill since each hammer can be turned four times, extending the mill's productivity. Optimal hammer design and placement will provide maximum contact with the feed ingredient. The durable design of the drive bearings and shaft also help to keep maintenance costs down.

Get Price -

PelletMasters Hammer Mills

Pellet Mills for Wood . Single Phase Electric Powered; Three Phase Electric Powered; Diesel Powered; PTO Driven; Pellet Mills for Feed and Fertilizer. Single Phase Electric Powered; Three Phase Electric Powered; Gasoline Powered; Diesel Powered; PTO Driven; Non Powered Pulley Drive; Non Powered Shaft Drive; Large Pellet Mills; Hammer Mills. Single Phase Electric Powered

Get Price -

hammermilldesignminiproject SlideShare

Apr 12, 2016· The PC hammer crush (hammer mill) was developed for both dry and wet crushing of brittle, mediumhard materials for the mining, cement, coal, metallurgic, construction material, road building, and petroleum chemical industries. Hammer Mill Features Material is reduced by impact from freeswinging bar hammers.

Get Price -

Buy and Sell Used Hammer Mills at Equipment

Used Bliss Eliminator Hammer Mill, Model E 4430 TF, Carbon Steel. 44" Diameter x 30" wide. (96) Approximate 6" long x 1/4" thick swinging hammers. Driven by a 250 HP, 3/60/460 volt, 1780 rpm motor. Openings top: 29" x 12", (2) hinged side access doors 30" wide x 52" tall, bottom discharge. Approximate 1/8" diameter screen size.

Get Price -

hammer mill design pdf[crusher and mill]

Download Hammer Mill Design Find Hammer Mill Design Downloadable Pdf Hammer mills : hammermills Feed Milling | . When the tip speeds exceed 23,000 feet per minute, careful consideration must be given to the design of the hammer mill, the materials used in its construction, .

Get Price -

Design and Development of a Petrolpowered Hammer mill .

Design and Development of a Petrolpowered Hammer mill for rural Nigerian Farmers. Adekomaya,, and Samuel, Department of Mechanical Engineering, Olabisi Onabanjo University, Nigeria *Corresponding Author: oludaisiyetunde Abstract A conventional hammer mill is a device consisting of a rotating head with free swinging hammers,

Get Price