-

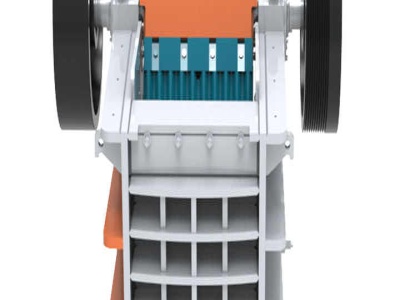

milling process of coal Crusher Machine For Sale

Coal milling plant with coal crusher and coal mills is for coal milling process in coal mining. Customers want, and that is our goal, we produce ore crusher( milling process of coal ), mill, crusher, mobile crushing plant, processing equipment, according to the specific needs of our design and production lines, fully the interests of customers.

Get Price -

Coal Mining and Processing | Energy Trends Insider

To remove coal in these underground mines, miners ride elevators down deep mine shafts where they run machines that dig out the coal. Processing the Coal After coal comes out of the ground, it typically goes on a conveyor belt to a preparation plant that is located at the mining site.

Get Price -

Coal mills for all requirements | Gebr. Pfeiffer

Coal grinding using available process gases. Coal, lignite or petcoke are ground in the Pfeiffer vertical mill by using available hot process gases. The grinding plant can be inerted. The raw coal is dried while being ground in the mill even if feed moisture exceeds 25%. The feed size that can be handled is up to 100 mm, making twostep precrushing unnecessary.

Get Price -

coal mill process plan

Coal Mill Process Plan. process of coal mills in power plant primaryteachers. coal mill in power plant coal mill. Coal grinding process is the surface area of the . Get Price And Support Online. process of coal mills in power plant csdpmap. Power Generation from Coal . A project to examine coalfired power plant efficiency and performance

Get Price -

Coal vertical mill_cement production process_lvssn

Coal vertical mill is a mechanical device used to pulverize coal for combustion in steam generator of fossil fuel power plant. Enable Ginger Cannot connect to Ginger Check your internet connection or reload the browser Disable in this text field Edit Edit in Ginger Edit in Ginger × rame scrolling="no"> rame> Enable Ginger Cannot connect to Ginger Check your internet connection

Get Price -

grinding roller manufacturing process for coal mill

Coal mill also called coal pulverzier or coal powder mill is grinding mill ... mill which only process fine coal ... coal grinding mill production line ... >>TYY LXP grinding mill roller housing manufacturer .

Get Price -

Coal Mill |authorSTREAM

Process introduction The coal mill can be divided into low speed coal mill medium speed coal mill and high speed coal mill. These three kinds of coal mills have their own good points customers can choose each one suitable for production according to the actual demands.

Get Price -

Coal mill in cement manufacturing process Manufacturer ...

Coal Mill an overview ScienceDirect Topics With any industrial activity, generation of waste and byproducts is expected In the case of cement manufacturing, the associated process leads to pollution in the following ways: Dust generation in specific sections of cement plants crushers, raw mill, coal mill, kiln, clinker cooler, cement mill

Get Price -

coal mill processes

In coal milling for power stations, a 'closedloop' process is used in which the rejects from the classifier are returned to the mill for regrinding. In VSMs, the recirculation loop is within the mill, but some mill types would have an external loop.

Get Price -

(PDF) Grinding Characteristics of Coal and Petroleum Coke ...

Petroleum coke (PC) blend with coal is an attractive feedstock for combustion process. The present work investigates the grinding characteristics of PC blend with coal in a laboratory ball mill to ...

Get Price -

Best Practices for the Design and Operation of Coal Mill ...

Oct 07, 2019· Coal mill dust collectors have a substantial effect on productivity, yet have received relatively little attention as companies implement costsaving programs, like the use of petcoke as a fuel reduction measure. Petcoke is typically ground finer than coal, and it has a particularly sticky nature that makes it more difficult to clean from ...

Get Price -

Coal Mill Cement Process Flow

Home / coal mill cement process flow. ... Pulverized coal is a common fuel in a cement plant. Due to safety reasons, monitoring of CO concentration in coal bunkers and coal mills is an essential issue. ACC JCC Italcementi Group / Get Price. Date: Milestone: 23 August 1989 . Registered as a Company Limited . 30 April 1993 . Read more

Get Price -

Coal Mill,Coal Grinding Mill Hongxing Machinery

Coal mill is the equipment that is used to crush the coal and grind it into the coal powder. It is the important auxiliary equipment of pulverized coal furnace. The grinding process of the coal is the process that the coal is crushed and its surface area is in increase.

Get Price -

Steps in the Modern Steelmaking Process

May 16, 2019· The Modern Steel Production Process. Today, steel production makes use of recycled materials as well as traditional raw materials, such as iron ore, coal, and limestone. Two processes, basic oxygen steelmaking (BOS) and electric arc furnaces (EAF), account for virtually all steel production.

Get Price -

coal mill | Mill (Grinding) | Screw

It is driven by a planetary gearbox. The three grinding rollers, mounted in fixed position, are passed down on the table under hydraulic loading. Raw coal enters through the center of the mill and is deposited on the grinding table. Centrifugal force feeds the coal radially outward where it is ground between the roller tyres and grinding track.

Get Price -

Stirred mills for milling grinding | FLSmidth

Stirred mills Tower mills — simple, effective and cost efficient As lower ore grades and complex mineralogy are driving demand for more efficient fine grinding, you can depend on FLSmidth for a full range of finegrinding mills designed for easy shipment, simple erection and troublefree maintenance.

Get Price -

ABB process control and automation solutions for mines ...

Enterprise asset management system upgrade for a coal mine in South Africa Transitioning 11 mining operations to a unified version with more efficient operations and IT maintenance. ... Gearless Mill Drives Increased process availability, reliability and energy efficiency (English pdf Drawing)

Get Price -

Coal mill in cement process

In the cement manufacturing process, each producing 1 tons of cement grinding material at least 3 tons including fuel, clinker, gypsum, mixture and all kinds of raw materials, according to statistics, dry process cement production line grinding operation requires more than the consumption of power plant power accounts for about 60%, the raw material grinding accounted for more than 30%, coal mill about

Get Price