-

Lagging ThomasNet

Distrubutor of conveyor belting accessories, specifically pulley lagging. Available in sheet and spiral wrap lagging. Features factory hot vulcanization, steel backing plates, rustresistant metal retainers, and traction pads. Industries served include mining, agriculture, feed .

Get Price -

Lagging » Armstrong Equipment

CRAFTLAG®REPLACEABLE LAGGING. CraftLag is bonded to rigid backing, which is then formed to a specific diameter. CraftLag can be used with or without retainers and is ideal for mining, crushed stone, sand and gravel, cement, agriculture, food processing, .

Get Price -

REPLACEABLE

Slide Lag® Replacement Pulley Lagging for Drive Pulleys. Use . SLIDELAG ® EDGECROWN ® to create a crown on a flatface drive pulley. Standard conveyor engineering usually calls for a crowned surface on all drive pulleys. A crowned pulley is used to assist in tracking the belt or directing it back to the pulley center when the belt starts ...

Get Price -

Rubber Lagging Conveyor Pulleys In Hyderabad

Rubber Lagging Conveyor Pulleys In Hyderabad. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Get Price -

Jiaozuo Zhuoer Machinery Manufacturing Co.,Ltd

Jiaozuo Zhuoer Machinery Manufacturing CO., Ltd. is specialized in designing, producing and marketing new type Conveyor Products Services. Our products are widely used in bulk material handling industries including mine, power generation, cement, metallurgy, chemical and other fields.

Get Price -

China Material Handling Conveyor Pulley for Mining China ...

Bend Pulley: It is used for changing the motion direction of conveyor belt, or increasing the surrounding angle between conveyor belt and driving pulley. 3. Conveyor pulleys (driving pulley and bend pulley) mainly consist of shaft, shell, bearing, housing, hub and pulley lagging.

Get Price -

Midwest Mine Services – Ohio and Michigan Aggregate ...

Midwest Mine Services uses proven engineering, design and technology to provide our customers with the best solution to their conveyor material handling applications. Fabricate Our design team and trade personnel ensure that your project is constructed in a safe, cost effective and timely manner.

Get Price -

Examples of Pulleys in Everyday Life | Sciencing

Mar 13, 2018· Most weightlifting exercise machines make use of pulleys as a way to control the angle at which weights are lifted while keeping the weights themselves in a dedicated location. This makes the process of weight lifting safer and more effective for the user than free weights may be if used .

Get Price -

MINING PRODUCTS

by the latest stateoftheart metal working machines and a staff of qualified experts. ... the CKX ceramic lagging with partial vulcanization ensures resistance to wear and conveyorfriendly ... DOPPSTADT MINING BELT PULLEYS GURTTROMMELN

Get Price -

92 Best Slide Lagging images in 2019 | Pulley, Sun lounger ...

Aug 21, 2019 Explore hxrubber's board "Slide Lagging" on Pinterest. See more ideas about Pulley, Sun lounger and How to look better.

Get Price -

PCI, ProCal Innovations LLC. | PCI Pulley Lagging ...

Product Description. The term lagging describes the variety of elastomers used to coat the contact surface of a conveyor pulley. Its primary purpose is to enhance traction by increasing the coefficient of friction between the surfaces.

Get Price -

REMAGRIP REMASLEEVE Pulley Laggings and Belt Idler Sleeves

Ceramic material is suitable for pulley lagging, thanks chiefly to its specific properties of extremely high wear resistance provided by aluminium oxide (Al 2 O 3). It replaces traditional materials, because it provides higher profitability by considerably increasing the .

Get Price -

Conveyors

The Lusanga Conveyor Department was established in 2003, born from the current need from mining clientele for engineering services in regards to maintenance and refurbishment of existing conveyance systems. ... Pulley lagging insitu . Comments are closed.

Get Price -

uses of pulley lagging machines in mining

uses of pulley lagging machines in mining. Pulley Lagging – Docstoc – Documents, Templates, Forms, . Legal > Patents > Machine Parts. Tags: . or the mining industry . Referring to FIG. 1 there is ...

Get Price -

germanBelt® Group Mining Technology | Mining News and ...

Coated pulley bottoms and transport sealing are among our extra services, which anticipate all your potential needs. Rubber friction lagging and ceramic friction lagging The application of germanGrip lagging materials greatly improves the pulleys' coefficient of friction and, through the lagging material's extreme grip, makes reduction of belt tension possible.

Get Price -

Ceramic Conveyor Pulley Lagging | Products Suppliers ...

...is also used to protect the surface of the roller or pulley from damaging media such as rocks, abrasive materials, and or chemicals. Pulley and roller lagging is often used in conveyor applications. Materials Pulley and roller lagging materials often...

Get Price -

Blog | Conveyor Pulleys Rubberfix Pty Ltd

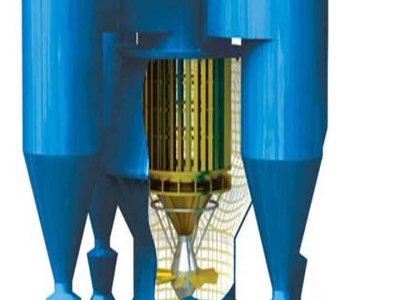

Troughing idlers are used to impart mining conveyor systems with a Ushaped materialhandling profile. When a belt sits on a series of troughing fittings, it takes on a long, scooplike outline. And what's the reason for adding this shape to a conveyor ribbon?

Get Price -

Pulley Lagging ThomasNet

Lagging is used to coat the contact surface of a conveyor pulley for enhanced surface tractions, lowered the belt tensions and reducing abrasive conditions between the pulley and belt. Made in the USA.

Get Price -

SlideLag Holz Rubber

Use SLIDELAG® EDGECROWN® to create a crown on a flatface drive pulley Standard conveyor engineering usually calls for a crowned surface on all drive pulleys. A crowned pulley is used to assist in tracking the belt or directing it back to the pulley center when the belt starts to wander. Eliminating erratic lateral belt movement is

Get Price