-

iron ore beneficiation process ppt Minevik

May 21, 2019· Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal process of iron ore beneficiation has two complementary goals and these define the methods used to refine it.

Get Price -

Extraction of Iron, Iron Extraction Process, Iron Ore ...

Strong magnetic iron ore belongs to freemilling mine, which can get highgrade iron concentrate with weak magnetic separation process. With the improving demand of iron ore concentrate, Xinhai has speeded up the research and innovation of magnetic iron ore dressing technology and magnetic separation equipment in recent years, and achieved remarkable results.

Get Price -

Iron Ore Smelting Process Brighthub Engineering

Introduction to Iron Ore and Steel Smelting Processing. Here the ore is put into a blast furnace along with limestone and coke and subjected to hot air blasting and heat which converts the ore to molten iron. This is tapped from the bottom of the furnace into molds known as pigs and allowed to solidify into pig iron.

Get Price -

Iron Ore Screening Process

Iron ore mining process and iron ore mining equipments minevik. Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening.

Get Price -

Iron Ore Pelletizing Process: An Overview | IntechOpen

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter shows the status of the pelletizing process ...

Get Price -

Iron ore mining process and iron ore mining equipments SBM

Mining and processing of iron ore involves coarse crushing and screening. Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening. This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse.

Get Price -

Iron Ore,Production Process of Iron Ore,Iron Ore ...

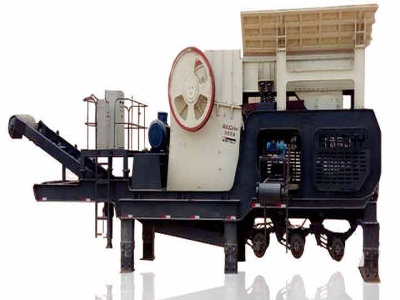

Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill, Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer.

Get Price -

Ore Beneficiation an overview | ScienceDirect Topics

Jan 04, 2007· Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so .

Get Price -

screening of iron ore

screening process for iron ore screening process for iron ore. SUAMG Machinery is professional mineral processing equipment manufacturer in the world, not our equipment has the excellent quality, but also our product service is .

Get Price -

iron ore screening equipment cost

Iron Ore Screening Plant Equipment Manufacturer in mxico,Shanghai SKD is a professional ore crusher equipment,Iron Ore Screening Plant Equipment Manufacturer in mxico iron ore wet lump screening cost SKD Mining. equipment cost for desorption electrolysis system iron ore

Get Price -

What Is Iron Ore Beneficiation? (with pictures)

Oct 26, 2019· Iron ore mining often focuses on looking for hematite deposits known as red iron ore, and magnetite, as they have naturally weak magnetic fields that aid in their purification. Hematite, however, responds better to the flotation process in iron ore beneficiation than magnetite, so it is the preferred type of ore.

Get Price -

what is iron ore screening process

what is screening process in iron ore ; Iron Ore Crushing,Iron Ore Screening,Crusher Plant,Vibrating Screen When large blocks are transported from iron ore mines, the crushing process is ready for rocks ...: ; Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned.

Get Price -

what is iron ore screening process

BENEFICIATION OF IRON ORE National Institute of ... BENEFICIATION OF IRON ORE ... process has to be advanced to reduce the waste generation in mines and for the sustainable ... Fig Graphical depiction of grade wise distribution of hematite ore 3 Fig Dry screening process 9 Fig Wet screening ...

Get Price -

Iron Ore | Geoscience Australia

May 03, 2017· Highgrade hematite ore is referred to as direct shipping ore (DSO) because, once mined, the ore goes through a relatively simple crushing and screening process before being exported for use in steel making. Australia's hematite DSO from the Hamersley province averages from 56% to 62% iron.

Get Price -

(PDF) Iron Ore Pelletizing Process: An Overview

Bentonite is an effective, widely used binder in the iron ore pelletizing process. Its low price is

Get Price -

iron ore cushing screening process « BINQ Mining

Jun 28, 2013· Iron ore crushing and screening equipment, mining process . A process adopted to upgrade ore is named Beneficiation. Iron ore is upgraded to a .

Get Price -

Iron ore pelletizing systems Metso

Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process. Also during the processing of high grade iron ores which don't need beneficiated, fines which are generated can be pelletized and used instead of being disposed of.

Get Price -

Iron Ore Screening Process

screening process for iron ore Processing Roy Hill. Roy Hill's purpose built, world class mine processing plant utilises low risk, proven technology to process 55Mtpa (Wet) of lump and fines iron ore and is the largest bands, which are difficult to handle in a dry crushing and screening process.

Get Price