-

Revitalising St Marys Cement

The latest, muchneeded, modernisation improves the raw mill, main pyroprocessing line, finish and coal mills, reflecting the considerable changes of the past 40 years, says Celso Martini, vice president of cement operations at Votorantim Cimentos North America.

Get Price -

Coal Mill In Cement Manufacturing

The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement. . the Coal Crusher is stored in a longitudinal stockpile from where it is reclaimed by a reclaimer and taken to the coal mill hoppers for grinding of fine coal. ...

Get Price -

What is the manufacturing process of cement? Quora

Aug 15, 2017· Basically, cement is produced in two steps: first, clinker is produced from raw materials. In the second step cement is produced from cement clinker. The first step can be a dry, wet, semidry or semiwet process according to the state of the raw material. The cement manufacturing process is described below.

Get Price -

Function Of Vertical Raw Mill Used In Cement Plant

function of coal mill in cement plant (basic coal mill function in cement plant) is a professional manufacturer of grinding mills ... Function Of Vertical Raw Mill Used In Cement Plant Protable . Read more

Get Price -

Cement Grinding Mills Process Manufacturing Plant Crushing

Rotary Kiln Cement Mill Cement Production Line Coal Mill Dust Collector Cement Plant Electrostatic ... Maker Spiral Washer Spiral Separator Tumbling Mill Sand Mixer Slag Mill Quarry Equipment Sand Screening Machine VSI Crusher Sand Manufacturing Process Glass Crushing Machine Puzzolana Crusher Stone Crushing Machine Drum Screen Quarry Crusher ...

Get Price -

Pet Coke Cost In Vertical Coal Mill In Cement Process

C5 Vertical Coal Roller Mill Cement manufacturing Coal Coal Pet Coke. A cement kiln is a proven . Comparative Properties of Coal and Petcoke. Coal and Petroleum Coke as Fuels in Cement Kilns. Bituminous coal has been in use as fuel in cement kilns for a long time. With coal costs process, various . grinding coke process Pet Coke Cost In Vertical Coal Mill In Cement Process. How .

Get Price -

Cement coal mill

Cement Coal Mill Cement Coal Mill Suppliers And. About 23% of these are mine mill, 1% are flour mill A wide variety of cement coal mill options are available to you, There are 3,219 cement coal mill suppliers, mainly located in Asia The top supplying countries or regions are China, India, and South Korea, which supply 99%, 1%, and 1% of cement coal mill respectively

Get Price -

mill function in cement industry

Coal in the cement industry Yasin. Coal in the cement industry Cement manufacturing consists of raw meal grinding, blending, pre calcining, clinker burning and cement grinding Limestone, CaO, SiO2, Al2O3 and Fe2O3 are crushed and milled into a raw meal This is blended and preheated in a preheater cyclone [Chat Online] OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:,

Get Price -

Use of coal as a fuel in cement plants and its impact on ...

local coal, in cement manufacturing, its formulation for blending with raw mix and its impact on raw material and clinker parameters. Results and Discussions The chemical composition of normal raw mix for high strength Portland cement is shown in Table1. Calculated amount of coal ash was added to

Get Price -

Cement Making Plant

Cement mill also plays a key role in the cement making plant, which is one of the major cement equipment, is the material to be broken, and then to smash the key equipment. In cement production line and cement manufacturing process plays a crucial role.

Get Price -

duties and responsibilities of cement raw mill opera

Job description Role • Testing of physical properties of raw material, raw mill, clinker and cement What is the role of a mechanical engineer in a cement Nov 14, 2015· There are various roles of a mechanical engineer in a cement plant.

Get Price -

Cement Manufacturing Process Civil Engineering Blog

Aug 27, 2015· In modern technology of dry process, the coal brought from the coal fields is pulverized in vertical coal mill and it is stored in silo. It is pumped with required quantity of air through the burners. The preheated raw materials roll down the kiln and get heated in such an extent that the carbon dioxide is driven off with combustion gases.

Get Price -

Cost Of Construction Of Cement Coal Mill

What Is Role Of Coal Mill In Clinker Manufacturing Process Cement Mill Process Manufacturerscement classifier Separator coal etcIn the process of cement production the cement clinker grinding process concrete mill plays an important role too. Materials; Cement Manufacturing Plant Cost Cement . For making cement raw materials bauxite is crushed ...

Get Price -

coal mill manufacturers for cement plant

coal mill manufacturers for cement plant. Cement Making Plant Cement mill also plays a key role in the cement making plant, which is one of the major cement equipment, is the material to be broken, and then to smash the key equipment.

Get Price -

Report on Cement manufacturing process

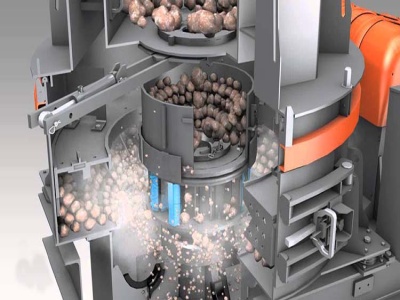

Jul 08, 2016· Industrial Internship Training Report 201516 | 26 Cement mill A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills, which are more effective than ball mills.

Get Price -

A Review On Environmental and Health Impacts Of Cement ...

A Review On Environmental and Health Impacts Of Cement Manufacturing Emissions Shraddha Mishra, Dr. Nehal Anwar Siddiqui ... In this paper, the role of cement industry is reviewed in causing impact on environment and health. It describes the cement production process and its emission sources followed ... in a cement mill to control the ...

Get Price -

coal mill cement industries

Thermal Energy Audit of Kiln System in a Cement Plant ... raw mill, coal mill ... In India the thermal energy consumption in cement industries varies from GJ to ...

Get Price -

Talking about the safe production of coal mill system in ...

Talking about the safe production of coal mill system in cement factory . ... The coal mill system needs to set the venting port at the appropriate position, including: the original coal bunker top (the closed coal bunker), the pipe mill to the classifier pipe, the mill, the fan, the screw conveyor, the unloader, the mill To the dust collector ...

Get Price -

The Cement Sustainability Initiative (CSI)

The work carried out by the Cement Sustainability Initiative (CSI) is officially transferred from the World Business Council for Sustainable Development (WBCSD) to the Global Cement Concrete Association (GCCA) as of 1 January 2019.. For archived information about the CSI, please visit here.. For access to the Getting the Numbers Right (GNR) 2016 data, please visit here.

Get Price -

cement production head roles responsibilities

Thus Portland cement began its predominant role Isaac Charles Johnson further refined the production of mesoPortland cement, The production of cement kilns, .... role of coal mill in cement manufacturing

Get Price -

coal mill cement industries

Coal mill (coal pulcerizer) is the essential machine used in cement plant, because coal is the important raw materials in cement production line. Get Price ThyssenKrupp Industrial Solutions Cement Industry .

Get Price