-

HIGH INTENSITY GRINDING ISSUE 32 AT ITS FINEST

challenges, particularly for grinding technology. Energy efficiency is a major driving force and another challenge to address. The High Intensity Grinding (HIG) mill has been designed specifically to manage these type of complex, fine grained orebodies that are rapidly becoming more economically viable. While this technology has

Get Price -

Grinding wheels and Segments Schleifscheiben

grinding zone by using an open structured wheel; this reduces the risk of burning. The structure of a grinding wheel can be controlled by the use of pore inducers type, size and amount to suit the individual application. Structure The structure of a grinding wheel is denoted by a number from 1 to 18 which relates to the spacing between

Get Price -

Innovations in Grinding of Modern Materials

Innovations in Grinding of Modern Materials . Dr. K. Philip Varghese/ Group Leader / SaintGobain Abrasives . With help from SG Colleagues (David Graham, Andrew Biro, Mike Shappell, John Hagan)

Get Price -

Mathematics and Control Engineering of Grinding Technology ...

Mathematics and Control Engineering of Grinding Technology Ball Mill Grinding. Authors: Keviczky, L., Hilger, M., Kolostori, J. Free Preview

Get Price -

PrecisiON GriNDiNG WHeeLs 2011 Catalogue

PrecisiON GriNDiNG WHeeLs 2011 Catalogue eNGLisH a126756_WTG_Precision_ 1 16:22. TabLe Of cONTeNTs WiNTerTHur TecHNOLOGy GrOuP 5 Company History and Portrait 5 Winterthur Schleiftechnik AG Innovative grinding technology of world renown Quality First 6 .

Get Price -

Dispersing Technology

Dispersing Technology PCA 2016 11 In general, the amount of dispersing agent, which is determined in the experimental method A, is too low. The reasons are: • the optimum degree of grinding is not achieved, because the amount of dispersing agent or binder during dispersion is too low (⇒ basics of pigment grinding)

Get Price -

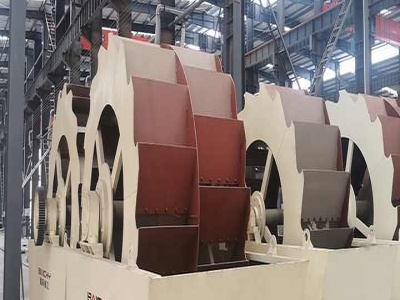

Metso comminution solutions Grinding

technology and industrial knowledge to deliver high efficiency and performance. Our robust mill designs withstand rugged and tough conditions provide high uptime and long life. Today, Metso is known as a world leader in horizontal mills. With a wide range of field applications our horizontal grinding mills are optimal for both wet or dry grinding.

Get Price -

Principles of Modern Grinding Technology by W. Brian Rowe ...

Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, grinding machine design, highspeed grinding technology, cost optimization, ultraprecision grinding, process control developments, vibration control, coolants and fluid delivery.

Get Price -

PROJECT TITLE Energy Efficient Grinding Technology ...

PROJECT TITLE Energy Efficient Grinding Technology Identification and Evaluation PROJECT OVERVIEW Identify and advance newtoindustry grinding technologies aimed at significantly reducing the energy required to functionally liberate minerals for selective recovery. PROJECT DESCRIPTION PROJECT STATUS Identifying new technologies.

Get Price -

HLMX Superfine Grinding Mill

Hong Cheng HLM grinding ... Combining several decades of powder mill RD and production experience and by introducing advanced technology from Taiwan and Germany, Honecheng has designed and developed the HLMX Superfine Vertical Mill ...

Get Price -

Grinding Anderson Feed Technology

Grinding. The Anderson Feed Technology is the result of over 100 years of experience and development in the cerealprocessing industry. Anderson Feed Technology hammer mills are supremely suited for the milling of products with a fibrous structure and a low density, for example dried alfalfa, straw, etc., as well as composite feeds that have a relatively high fat or moisture content.

Get Price -

Gear Technology and Automation Systems Liebherr

10 Gear Technology and Automation Systems Liebherr now offers this complex technology and will be presenting a skiving machine in 2017. Everything from a single source: machine, tool and process. The machine represents excellent quality and productivity when .

Get Price -

Optimization of grinding operation

With grinding operation we can achieve various objectives such as surface very well finished, or high accuracy, or tend to a better cutting capacity in order to remove a large amount of material in less time. But you can also find the conditions for the lowest cutting force and .

Get Price -

Enhancement of grinding performance based on .

precision grinding because they have higher truing and dressing abilities, compared with nonporous type wheels such as metal bonded cBN wheels. In order to enhance the grinding characteristics of vitrified cBN wheels, many studies on dressing condition, grinding condition [12], development of abrasives [3] and so on have been carried out.

Get Price -

Cryogenic Grinding | Seminar Report, PPT, PDF for Mechanical

Explore Cryogenic Grinding with Free Download of Seminar Report and PPT in PDF and DOC Format. Also Explore the Seminar Topics Paper on Cryogenic Grinding with Abstract or Synopsis, Documentation on Advantages and Disadvantages, Base Paper Presentation Slides for IEEE Final Year Mechanical Engineering ME or Production Automobile Students for the year 2015 2016.

Get Price -

GRINDING TECHNOLOGY STEPHEN MALKIN PDF

Apr 28, 2019· Grinding Technology : Stephen Malkin : Grinding Geometry and Kinematics. Simulation Optimization and Intelligent Control. Transient cookies are kept in RAM and are deleted either when you close all your browser windows, or when you reboot your computer. Grinding Technology, Second Edition pesents a comprehensive and brinding treatment of ...

Get Price -

TECHNICAL SOLUTIONS FOR GRINDING

Technology is a complementary range for specialized applications like fi ne grit ball wheels, cup wheels for tapered bearing, 30AS superfi nishing sticks, etc.. Vitrium3 bond is available under Efesis Technology to improve vitrifi ed product performances in precision grinding applications. EFESIS Technology VITRIUM3 Cutting edge, high

Get Price -

GEAR TECHNOLOGY

blade technology or TwinBlade. All encompassing solutions for the most demanding tasks in drive technology. We will work side by side with you to bring your ideas to realization. Because our achievement is measured on your success. For more information: For the USmarket please contact: Liebherr Gear Technology Inc. .

Get Price -

GRINDING WHEEL

A grinding wheel is a selfsharpening tool composed of discrete abrasive grains held together by a bonding agent with composite structure of many clearance allowance for the cutting edges. The characteristics of a grinding wheel depends upon the combined elements of abrasive, grit size, grade, structure and bond.

Get Price