-

How iron is made material, manufacture, making, history ...

The process of extracting iron from ore produces great quantities of poisonous and corrosive gases. In practice, these gases are scrubbed and recycled. Inevitably, however, some small amounts of toxic gases escape to the atmosphere. A byproduct of iron purification is slag, which is produced in huge amounts.

Get Price -

Slag Atomising Technology (SAT): Strategic management of ...

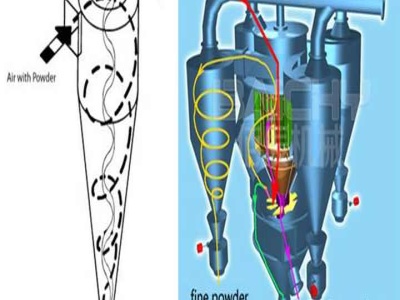

Processing of EAF using traditional methods involves crushing and grinding. However, the new technology of atomising molten slag is an innovative process that produces highspecification products with multiple uses. Slag Atomising Technology (SAT) is invented, patented and commercialised by Ecomaister Co., Ltd of Korea.

Get Price -

MPA Mineral Products Association Products

Here it is tipped and cooled prior to onward processing. The AOD process is a secondary steel making process for the refinement and manufacture of different grades of stainless steels in a ladle furnace. This process produces a slag that is then further treated to prevent dusting of the aggregate.

Get Price -

How to reduce the amount of slag produced in the galvalume ...

How to reduce the amount of slag produced in the galvalume steel sheet process – Professional Steel Coil Manufacturer. Large amount of slag production during the galvalume steel sheet process is a very troublesome thing. It will not only increase the workload of slag, but .

Get Price -

Making Vanadium | Vanitec

Vanadium bearing coproduct slag is generated during steel production from iron sands in New Zealand in a process similar to the South African process. The iron from these operations contains about % vanadium which is removed as slag by low temperature treatment with oxygen.

Get Price -

Ground Granulated Blast Furnace Slag an overview ...

Slag is primarily composed of CaO, SiO 2, aluminum oxide (Al 2 O 3), and magnesium oxide (MgO). When used as part of a portland cement concrete, slag reacts with both the water (latent hydraulic reaction) and the hydrated cement paste (pozzolanic reaction), resulting in a more refined microstructure than that of a plain portland cement.

Get Price -

processing machine slag

processing produces slag driewielerspecialist. The metal working industries process metals in order to manufacture machine components, machinery, instruments and tools which are needed by other industries as well as by the other different sectors of the economy. slag processing plant iron ore slag mill processing plants for sale iron slag ...

Get Price -

Iron Ore Smelting Process Brighthub Engineering

This process prepares it for the next stage which is the heating and forging to the desired wrought iron designs and shapes. This used to be an art of the blacksmith, but is now normally carried out by machines. Steel Process. This process is used to remove impurities from the pig iron produced in .

Get Price -

Slag Cement Association

Slag cement is a recovered byproduct of the iron manufacturing process and can be used to replace a portion of portland cement in concrete mix design. The use of slag cement has demonstrated longterm performance enhancements allowing designers to reduce the environmental footprint of concrete while ensuring improved performance and increased ...

Get Price -

RECYCLING OF STEELMAKING SLAG FROM ELECTRIC ARC .

slag produced in process of electric arc furnace steelmaking. Its character and composition are in close relation to the processes used for steel melt preparation in the

Get Price -

Income from waste: Ukraine can double slag processing and ...

The largest suppliers of slag for processing are ArcelorMittal Kryvyi Rih and UMG, which was founded by SCM in 2006 to manage raw material assets. Metallurgical slag is divided into several types: blastfurnace, steel and ferroalloy. Blast furnace slag is the most popular in Ukraine: it is a byproduct of pig iron smelting in a blast furnace.

Get Price -

Mine wastes management Mining and Blasting

Mine wastes management Mining wastes is generated during the process of extraction, beneficiation and processing of minerals. Extraction is the first phase that consists of the initial removal of ore from the earth. This is normally done by the process of blasting, which results in generation of large volume of waste (soil, debris and other ...

Get Price -

NATIONAL SLAG NSA 1814 ASSOCIATION

the German, Belgian, French cement industries started to produce slag cement, they all utilized their national iron ore which gives a basic slag. Examination of this data gives an idea of the different strength qualities that can be obtained from the two different types of slag, basic and acid, both produced by the "Classical" granulation process.

Get Price -

PRODUCTION, CHARACTERISTICS AND USE OF .

The cr ushed and screened slag products are produced from air cooled lumpy slag which is collected from various process phases, from ladles and launders. The slag is directly granulated during tapping where ferrochrome is tapped into ladles.

Get Price -

Electric arc furnace slag Euroslag

Electric arc furnace slag. Electric arc furnace slag is produced during the manufacture of crude steel by the electric arc furnace (EAF) this process steel scrap with additions of fluxes (, lime[stone] and/or dolomite) are heated to a liquid state by means of an electric current.

Get Price -

Review of 11th Global Slag Conference 2016

May 25, 2016· The process would be economic if the input cost of the slag into the process was zero, while it would be yet more profitable with a significant CO 2 price, since the process acts as a carbon sink, reducing emissions by CO 2 per tonne of PCC produced. A residual slag byproduct with moisture content of around 10% is also produced,which also ...

Get Price -

Understanding Electric Arc Furnace Steel Making Operations

The furnace is tilted backwards and slag is poured out of the furnace through the slag door. Removal of the slag eliminates the possibility of P reversion. During slag foaming operations, C is injected into the slag where it reduces FeO to metallic Fe and in the process produce CO which helps foam the slag.

Get Price -

Coal Ash, Fly Ash, Bottom Ash, and Boiler Slag | NRDC

The recycling process also renders the toxic materials within fly ash safe for use. Bottom ash is the coarser component of coal ash, comprising about 10 percent of the waste.

Get Price -

Copper Sulphuric Acid

The process is a continuous, multistep process which produces blister copper from concentrates in three interconnecting furnaces. Concentrate and oxygenenriched air (3035% O 2 ) enter the smelting furnace through vertical lances and are smelted to produce a matte of 65% to 69% Cu and lowcopper slag.

Get Price -

SBM – the SpecialiSt in the proceSSing of Slag

SBM – the SpecialiSt in the proceSSing of Slag For decades, SBM Mineral Processing has been planning and producing proven, efficient complete solutions for the processing of slag. Trendsetting plant concepts are the foundation of a value added chain which .

Get Price -

coal slag processing

A review of waste heat recovery technologies towards molten slag in ... input per tonne, which cost million tonnes of standard coal and discharged ... in ironmaking process and accordingly, steel slag is produced in steelmaking ...

Get Price -

Scrap Processing | Edw. C. Levy Co.

Processes include cutting, breaking, screening, and copper picking to produce various sizes of scrap for return to the furnace. This processing includes tundish skulls, ladle skulls, scrap coils, revert scrap, crop ends, and other various scrap.

Get Price -

Flocculation for improving the processing of slag from ...

It turned out that, from all studied reagents, the cationic C587 is suitable for the purpose. Some of reagents were studied for their ability to flocculate selectively, in presence of coke fines, rich in copper fines which are produced at grinding of a slag from leadzinc metallurgy.

Get Price -

Its processing produces slag Crossword clue | Crossword ...

Its processing produces slag Find potential answers to this crossword clue at

Get Price -

Mineral Resource of the Month: Iron and Steel Slag | EARTH ...

Iron and steel slag, also known as ferrous slag, is produced by adding limestone (or dolomite), lime and silica sand to blast furnaces and steel furnaces to strip impurities from iron ore, scrap and other ferrous feed materials and to lower the heat requirements of the iron and steelmaking processes.

Get Price