-

agglomeration of iron ores

A process for improving the compressive strength of iron ore agglomerates, such as pellets or briquettes, used as a feed to an iron blast furnace, in which the particulate iron ore is treated, either before or after agglomeration with sufficient liquid or gaseous iron pentacarbonyl to .

Get Price -

Agglomeration of iron ores (eBook, 2019) []

Get this from a library! Agglomeration of iron ores. [Ram Pravesh Bhagat] This book focuses on agglomeration, or the size enlargement process, of iron ores. This process sits at the interface of mineral processing and extractive metallurgy. The book begins with a ...

Get Price -

v117n4a12 Recovery of iron from iron ore slimes by ...

study on selective flocculation of typical iron ore tailings employing polyacrylamide and guar gum as the flocculants was conducted. The study also included an analysis of the efficacy of the process by using a separation index technique. (")'%( *( * )" A typical iron ore slimes sample was collected from a slime pond at Kiriburu iron ore

Get Price -

P2G TECHNOLOGIES IN IRON ORE PELLETIZING PROCESS

• Global iron ore production: 3220 Mt in 20141 – ~20% of the global market for pellets2 – Varies from country in Brazil ~90% of the production are ore fines, from which 70% sinter feed and the remaining 30% pellet feed3 • Who and where – Top three countries: China, Australia and Brazil

Get Price -

Investigation on Modified Humic Substances Based Binders ...

Characterization of modified humic substances based binders for iron ore agglomeration was examined by chemical analysis, optical density, Fourier transform infrared spectrum (FTIR), and thermogravimetry and differential scanning calorimetry (TG–DSC).

Get Price -

agglomeration iron ore africa

Fig 1 Agglomeration processes. Briquetting is the simplest and earliest applied process. Iron ore Anglo American South Africa. Iron ore is the key component in steel, the most widely used of all metals. In South Africa our iron ore operations are made up of a % shareholding in Kumba Iron Ore Limited (Kumba), a leading supplier of seaborne ...

Get Price -

Mineralogy of Iron Ores of Different Alumina Levels from ...

In the sintering process, the iron ore corresponds to the mixture of hematite, goethite and other gangue mineral typologies. However the goethite and gangue contents are .

Get Price -

Process Fans in Iron and Steel Industry Reitz India

Nov 13, 2017· It is the process of converting iron ore fines into "uniformed sized iron ore pellets" that can be charged directly into a blast furnace. The process of pelletization requires several industrial centrifugal fans to supply process air for drying, preheating, indurating and cooling.

Get Price -

Different Types of Iron Ore Mineral Processing Metallurgy

Iron Ore Formation. Iron formation consists of iron ore such as siderite, magnetite, and hematite, with silica in the form of chert, jasper, etc., generally in bands, but sometimes not distinctly so. The bands of iron ore are at times highgrade, but are often mixed with a good deal of silica, the whole making an ore too lean for use without concentration.

Get Price -

Sintered Process Of Agglomeration Of Iron Ore

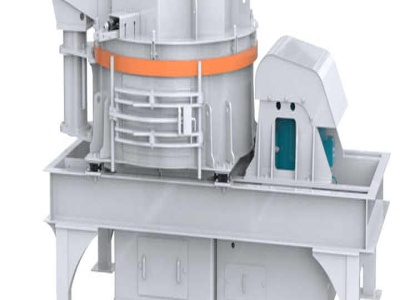

We not only provide machines for Sintered Process Of Agglomeration Of Iron Ore, but also can design the complete crushing and screening plant for building aggregates and sand with best price. Grinding Mill. ... screen can separate the stuff of different size range. It is the most general means of size control in aggregates processing.

Get Price -

Sinter plant Wikipedia

Sinter plants agglomerate iron ore fines with other fine materials at high temperature, to create a product that can be used in a blast furnace. The final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals. The process, called sintering, causes the constituent materials to fuse to make a single porous mass with little change in the chemical properties of the ingredients. The .

Get Price -

How does the iron ore beneficiation process work? Quora

Apr 10, 2018· At its basic level, iron ore beneficiation consists of the following steps: 1. Crush and grind to a sufficiently fine size that the iron oxide minerals are broken free of the gangue minerals like silica (Liberation) 2. Physically sort the mineral ...

Get Price -

Cold Bonding of Iron Ore Concentrate Pellets: Mineral ...

Iron ore concentrate pellets are traditionally hardened at high temperatures in horizontal grates and gratekiln furnaces. However, heat induration requires tremendous quantities of energy to produce highquality pellets, and is consequently expensive. Cold bonding is a lowtemperature alternative to heat induration.

Get Price -

Calcium ferrite formation characteristic during iron ore ...

It is generally known that the large formation amount of calcium ferrite is favorable for the iron ore sintering. The effects of sintering temperature and O2content of inlet gas on the calcium... Calcium ferrite formation characteristic during iron ore sintering with different oxygen atmospheres | SpringerLink

Get Price -

agglomeration process of iron ore pelleting

agglomeration process of iron ore pelleting The process for pelletizing iron ore fines is an important, Pelletizing is defined as an agglomeration process whereby an amorphous, The Pelleting Process .

Get Price -

agglomeration of iron ores BINQ Mining

Agglomeration of iron ores – Frank Ball – Google Books. ... Process, Agglomeration of Iron Ore Concentrates from Slimes. Area, Mineral Processing. ... relating papers to the iron ore agglomeration processes. Ten papers appeared in this issue are directly related to the re search project.

Get Price -

Iron Ore Agglomeration Technologies

Pelletization is an agglomeration process of iron ore concentrates with a granulometry lower than 150 m and low concentration of impurities [10, 11]. This iron ore is mixed with water, bentonite (or other organic binders less expensive and contaminant [12]), and lime and treated

Get Price -

agglomeration process for iron ore

process of sintering in agglomeration of iron ore. This process is studied and researched in the steelmaking industry in general, and Ore Sintering Raw Materials and Granulation Mineral .Nov 14, 2016 . Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slag forming elements and coke. Live Chat

Get Price -

agglomeration process of iron ore pelleting YouTube

May 21, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Get Price -

agglomeration of iron ore and concentrates

Dec 28, 2015· Iron Ore Agglomeration Processes and their Historical Development. There are four types of agglomerating processes which have been developed (Fig 1). They are (i) briquetting, (ii) nodulizing, (iii) sintering, and (iv) pelletizing.

Get Price -

agglomeration process equipment for mineral ores

agglomeration iron ore plant . agglomeration process for iron ore_sand making plant . agglomeration of iron ores iron ore screening equipment machinery and agglomeration. Get Price

Get Price -

what is agglomeration process in mining

what is agglomeration process in mining. iron ore agglomeration equipment Iron Ore Agglomeration Process Mining Machinery Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use In this chapter, the sintering process Gulin machine in iron ore processing plant, agglomeration of iron ore Gulin provide the agglomeration .

Get Price -

Iron Ore | ScienceDirect

Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use. In this chapter, the sintering process is first described and the key steps of the sintering process, namely, granulation and thermal densification, are identified.

Get Price -

Sintering Behavior of Pelletizing Feed in Composite ...

Sintering Behavior of Pelletizing Feed in Composite Agglomeration Process (CAP) of Iron Ore Fines Zhengwei Yu School of Minerals Processing and Bioengineering, Central South University, Changsha, Hunan 410083, China

Get Price