-

CHAPTER 11 IRON AND STEEL PRODUCTION Flashcards | Quizlet

CHAPTER 11 IRON AND STEEL PRODUCTION. a) The gas stream carrying dust particles enter the precipitator has a negative charge b) Dust particles are electrostatically charged plates hacve a .

Get Price -

Vale opens largest iron ore mine in its history

Dec 18, 2016· Vale SA (NYSE:VALE) cut the ribbon on a massive iron ore mine in Brazil on Saturday – the largest in its history and what the world's largest iron ore producer says is the biggest ever in the ...

Get Price -

On the Production of Iron Ore Superconcentrates by High ...

For this application an iron ore superconcentrate containing less than 2 pct silica is demanded. Pilot plant and commercial operations have shown that highintensity wet magnetic separation is well adapted to meet this specification with high recovery and attractive capital and operating costs.

Get Price -

Minerals Processing DRA Global

Scope of work on the processing plant included the design and construction of a facility to treat Mtpa of oxide ore through the oxide circuit, and Mtpa plant for the treatment of sulphide ore through the sulphide circuit. Although the project deadline was brought forward, DRA Global achieved first gold pour a month ahead of schedule.

Get Price -

CDE Combo Brochure Advance Wet Processing Solutions ...

The Combo does all this, with an impressive capacity range to suit most material washing applications. CDE Combo Brochure Advance Wet Processing Solutions CDE Global The CDE Combo™ is the first in the global washing industry to combine feeding, grading, washing, water recycling and stockpiling onto one compact chassis.

Get Price -

Engineer Control Systems | FIFO Mine Roy Hill

Roy Hill's purpose built, worldclass mine processing plant is the largest and most advanced single feed plant in the Pilbara and utilises low risk, proven technology to process 55Mtpa (Wet) of lump and fines iron ore. Our Processing Operations leadership team is now seeking an experienced Engineer Control Systems to join the group on an 8:6 Days Nights Roster from Perth. Reporting to the Specialist .

Get Price -

Vale's Q2 Iron Ore Production Drops 34% Due to Dam Disaster

Jul 23, 2019· The company anticipates the Brumadinho dam rupture to have impacted its iron ore annualized production by about 93 Mt. Earlier in June, Vale had announced that it .

Get Price -

how does iron ore wet processing plant work

Search how does iron ore wet processing plant work to find your need. Gulin Mining and Construction Machinery is a global manufacturer and supplier, We ... Gulin Mining and Construction Machinery is a global manufacturer and supplier, We ...

Get Price -

(PDF) Wet High Intensity Magnetic Separation of Iron Minerals

Wet High Intensity Magnetic Separation of Iron Minerals. The magnetic properties of these minerals were measured. The effect of particle size and magnetic susceptibility on wet high intensity magnetic separation was studied simultaneously. It was found that hematite—1 was a strongly paramagnetic mineral, and the effect of particle size in WHIMS was...

Get Price -

S. Komar Kawatra

presence of mineral and particul ate processing as an educational and research area at Michigan Tech. • Established a Coal Research Laboratory in the Depa rtment of Metallurgical Engineering. The laboratory consists of several test rigs such as hydroc yclone, waste stream analyzer for ash and iron ore, and column flotation cells.

Get Price -

Ore sorting Preceding processing | Ausenco.

Wet drum magnetic separators are typically used for heavy media applications, iron ore beneficiation, mineral processing and the reclamation or concentration of ironbearing minerals, with Eriez manufacturing multiple diameters, widths and tank designs in order to accommodate the various requirements for the metallic ore processing industries.

Get Price -

How Mining Works Resolution Copper

Here's how it works. Ore, rock containing economically recoverable copper, is extracted from the bottom of the ore body. A void, or cave, is then created. Ore above the void breaks up due to gravity and falls into the cave. Extracted ore is hauled to crushing facilities and broken into smaller pieces. Then the ore is hoisted to the surface.

Get Price -

Mining and processing Rio Tinto

Mining and processing. Today, the Argyle processing plant is one of the most efficient in the world. It is capable of processing up to 11 million tonnes of ore per annum. The Argyle mine and processing plant operate 24 hours a day, 365 days of the year.

Get Price -

Vale to Restart Wet Processing Operations at Brucutu Mine ...

Following the accident, Vale's Brucutu mine has been producing iron ore at an annual rate of 10 Mt, which is onethird of its total production capacity. It has been using 'dry processing' to ...

Get Price -

How iron is made material, manufacture, making, history ...

The iron content of these ores ranges from 70% down to 20% or less. Coke is a substance made by heating coal until it becomes almost pure carbon. Sinter is made of lesser grade, finely divided iron ore which, is roasted with coke and lime to remove a large amount of the impurities in the ore.

Get Price -

Sustainable mining a must to meet demand Australian Mining

Aug 14, 2019· This plant, which is currently in factory preassembly, will prove the value of the concentrated ore as a 70 tonne per hour pilot plant before moving to .

Get Price -

Dry processing of magnetic iron ores – addressing cost and ...

Dry processing of magnetic iron ores – addressing cost and environmental issues. W Skinner (1) and J R Kelly (2) AusIMM Iron Ore 2017 Conference, Perth, Australia, 2426 July 2017. Paper Number: 86. ABSTRACT. The Iron ore industry has reached the end of an unprecedented period of expansion triggered by China's demand for iron ore.

Get Price -

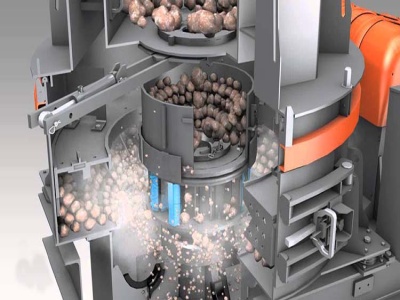

Rio Tinto Brockman 4 Iron Ore Mine, Pilbara Mining ...

Processing can be either wet or dry. The plant cuts ore into small particles and produces high graded haematite and magnetite materials. The haematite is segregated from magnetite through a gravity separation system. It will be further processed to extract top quality iron ore pallets.

Get Price -

Wet High Intensity Magnetic Separators (WHIMS) | WPE ...

Description. The Eriez GZRINM Wet High Intensity Magnetic Separator is a high gradient vertical ring magnetic separator. A DC current is applied to the coil to form a magnetic field in the separating compartment containing the matrix is a select type of magnetic iron .

Get Price -

Unlocking maximum value saleable tons from iron ore waste

Oct 14, 2019· Wet processing equipment company CDE has successfully helped bring an Australian iron ore miner back from the brink of closure through the innovative use of its technology and believes that this technology can be used to unlock value in the South African iron ore mining sector too, writes CHANTELLE KOTZE.

Get Price -

Vale's Iron Ore Production and Sales in Q3 2019 Results

Vale's iron ore fines production3 reached million tonnes in 3Q 2019, % higher than in 2Q19 and % lower than in 3Q18, mainly as a result of the resumption of Brucutu operations in June ...

Get Price -

WEST ANGELAS IRON ORE OPERATIONS Project in Newman, WA ...

ROY HILL IRON ORE PROJECT PACKAGE 1 MINE PROCESS PLANT TRAIN LOAD OUT Train Load Out project at 110km north of, Newman, WA 6753 in the Mining Primary And Secondary Processing (Minerals Processing).

Get Price -

Successful Projects Our Projects Mine Processing Plant

Feb 26, 2016· The tender stage of this project included design, procurement and construction of three iron ore processing plants. Working with the design, procurement and estimation team to prepare a detailed project schedule to demonstrate our client's ability to successfully deliver the project in the timeframe available.

Get Price