-

WEMCO ISF Hydraulically Induced Gas Flotation System

concentration in the range of 5–10 ppm. Our ISF cells are designed to provide 90% or greater oil removal and 80% or greater removal of nonoil solids at full design capacity. In contrast, conventional hydraulic flotation systems typically experience performance degradation at only 40% of .

Get Price -

Mechanical flotation cell | Article about mechanical ...

Looking for mechanical flotation cell? Find out information about mechanical flotation cell. A device that separates minerals from ore water pulp; it consists of a cell in which the pulp is kept mixed and moving by an impeller at the bottom of the...

Get Price -

Design Techniques for Mirror Cells

As a starting point, we use a 406mm (16 inch) diameter mirror, 54mm ( inch) thick, and use the cell design given in Kriege and Berry (which, BTW, is an excellent book!) Kriege and Berry use, written by David Chandler, to design their cells.

Get Price -

Flotation Tank Cells | Westpro Machinery

Flotation Tank Cells. Developed through an extensive RD process, Westpro's Flotation Tank Cells deliver industryleading flotation recovery performance in a variety of mineral processing applications. In addition to an optimized mechanism design, the Flotation Tank Cells include a number of features to facilitate operation...

Get Price -

Flotation – Denver Mineral Engineers

GOLD MINING WATER TREATMENT PROCESS EQUIPMENT. Home; Consulting Services; Gold Mining Process Development; Carbon Stripping; CIP History

Get Price -

Flotation: DAF, IAF, SAF Veolia Water

Flotation: DAF, IAF, SAF By Dave Christophersen, CWT Originally Published: CSTR December 2005 F lotation is a method of separating solids or liquids from water by introducing fine gas bubbles. The bubbles attach to the particulate matter, and the buoyant .

Get Price -

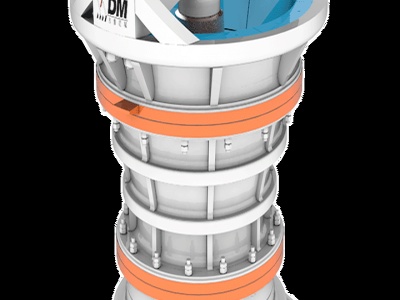

Column Flotation

column flotation, covering pilot testing and scaleup, circuit design of selected applications, and instrumentation and control. We begin with a description of the key features and concepts of column flotation. KEY FEATURES AND CONCEPTS . A schematic of a flotation column is shown in Figure 1. Industrial flotation columns are 614 m

Get Price -

Flotation Mintek

Mintek can develop and evaluate flotation procedures for new ores, according to specific product grade and recovery requirements, by applying its expertise on the selection of plant configuration, reagents, and conditions, and by running extended pilotscale testwork. It also offers a consultancy service to help existing plants. Equipment.

Get Price -

Forcedair flotation cell | FLSmidth

Specifically designed to maximise fine particle recovery, the DorrOliver flotation cell is the most energy efficient, technically advanced, forcedair flotation machine on the market. Its air dispersion capabilities exceed all competitive forced air designs – an important consideration for fine particle recovery.

Get Price -

DESIGN AND PERFORMANCE ASPECTS OF COAL FLOTATION ...

The Jameson Cell technology is an established robust and efficient high intensity flotation technology which has been continuously developed and improved over two decades. Its high capacity, small footprint and low maintenance requirements have made it more or less a standard flotation technology in the Australian coal industry.

Get Price -

flotation cell, flotation cell Suppliers and Manufacturers ...

4. The circulation of mineral slurry is reasonable, and flotation cell price can avoid the disposition of coarse sand to the largest extent. 5. There is selfcontrol device on the surface of mineral slurry, so flotation cell price is easy to adjust . 2.

Get Price -

Flotation Cells for Sale | New Used Flotation Cell ...

New Used Flotation Cells for Sale Savona Equipment is a flotation cell supplier worldwide. Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic. This is used in several processing industries. Historically this was first used in the mining industry.

Get Price -

14 Best Flotation Cells images | Stainless steel tanks ...

We have both rubber tire and rail equipment, crushing plants, underground and surface drilling, milling equipment including jaw crushers, cone crushers, roll crushers, flotation cells, cyanidation equipment, conveyors, used pipe, used fittings, pumps, and used electrical teck cable.

Get Price -

Hydrocell Induced Gas Flotation Separators

flotation (IAF), or induced gas floatation (IGF) separators are innovative, adaptable and affordable. The Hydrocell® separator is ideal for use where oil/water separation is required in large volumes, or where other organic matter must be removed from water or industrial effluents. For the removal of volatile organic compounds

Get Price -

Flotation Developments Best Practice International Mining

Flotation cell design. It comprises all the necessary hardware and software to conduct froth image analysis and reports information relating to bubble size, bubble count, froth colour analysis, froth stability, froth texture and froth velocity which is used to assist the control of the process.

Get Price -

Froth flotation circuit design and basic testwork ...

Testwork necessary to define the design parameters for a flotation circuit generally includes: Grindability studies to establish grinding power requirements Chemical and mineralogical analyses of test composites to establish ore grades, mineral associations and liberation characteristics

Get Price -

Comparison of column flotation cells (Conference) |

The flotation column technologies included in this study were the Jameson Cell, Flotaire, Turboair, PackedColumn, Microcel and the Canadian Column. The coal samples treated in this study were a {minus}100 mesh flotation feed slurry, a {minus}40 mesh coal, and a refuse pond coal sample.

Get Price -

Flotation | Mining | SGS South Africa

By visualizing and understanding the "hidden" factors of flotation cell hydrodynamics, SGS has the expertise to provide you with reliable data and solutions for more efficient flotation. Beyond flowsheet development and piloting of traditional flotation circuits, we offer you a comprehensive combination of flotation circuit expertise, technologies and equipment, including:

Get Price -

Flotation Wear Components Multotec

Flotation wear components from Multotec ensure your froth flotation operation delivers maximum mineral recovery performance. These highquality, hardwearing replaceable wet and dry components are available for all flotation cell types and sizes, and can be redesigned to optimise performance and life, as demanded by application.

Get Price -

JAMESON CELL

Commissioning is quick and simple. The cell can reach design capacity quickly after commissioning. 7. FLEXIBLE CELL DESIGNS. Cells are sized to accommodate the design ˚owrate based on the number of downcomers. The tank can be designed to ˜t into restricted spaces, making it ideal for retro˜ts/replacement and expansion projects.

Get Price -

Imhoflot Pneumatic Flotation Technology – Maelgwyn Mineral ...

The flotation cells are designed for a variety of throughput requirements, ranging from small pilot sized cells with a diameter of, processing 6 – 10 m 3 /h of feed; to cells with a diameter of, handling feeds of 1500 m 3 /h.

Get Price -

Report on flotation pilot plant design and arrangement

Components are Cell Design, Agitation, Air, FlowCell, Bank Configuration, and Cell Bank Control. The Industrial flotation system includes many interrelated components, and changes in one area will produce compensating effects in other areas. FIGURE 2. INDUSTRIAL FLOTATION PLANT FLOTATION .

Get Price -

Flotation cells for produced and process water treating ...

Flotation cells for produced and process water treating. These include multiple eductors in each cell to give greater crosssectional area of coverage for separation. Moving parts are minimized by replacing the typical mechanical oil wipers with an adjustable weir system for oil removal. Also featured are inlet surge cell with skimming, Clearwell (quiescent cell), and four active cells.

Get Price -

Column Flotation • Theory and Practice

Key Words : Column flotation, Theory practice, Applications. INTRODUCTION Separation of valuable minerals from gangue is far from ideal in conventional mechanical cells. Column flotation, invented in the early sixties, proved to be a better alternative to the conventional cells. The main advantages of column flotation are : i) improved recovery,

Get Price