-

A Clean Production Process for Producing NaSb(OH)6 from ...

Antimonybearing dust, a byproduct of the leadsmelting process, is an important secondary resource of antimony. A clean production process for producing NaSb(OH) 6 by oxidation in an NaOH solution has been proposed to solve the difficulties of recovering antimony from antimonybearing dust.

Get Price -

Antimony: 2019 World Market Review and Forecast to 2028

Antimony mine production forecast up to 2028 Antimony demand forecast by 2028 Detailed analysis of antimony market in a country is available covering data on capacity (by plant), production, consumption, trade, prices and market forecast.

Get Price -

COMPLETE BIBLIOGRAPHIES. FOR STUDENTS, .

the modern volatilisation process naturally finds but little mention. It seems likely, however, to become the sole process by which the poorer classes of antimony ores can be economically treated ; and as these ores are of rapidly growing importance, possibly as a result of the exhaustion of the richer grades of ore, a description of the

Get Price -

Antimony smelting process generating solid wastes and dust ...

Xikuangshan FlashAntimony Industry Limited Liability Company is a smelting plant in the Xikuangshan area with an annual production of 4 × 10 4 tons of antimony. The wastes produced in the smelting processes in the Xikuangshan area mainly include waterquenched slag (WQS), desulfurized slag (DS), arsenicalkali residue (AAR)...

Get Price -

What is Antimony Used for Metal Items

Today antimony is produced in a handful of countries, including China, which holds 75 percent of the world's reserves, and accounts for almost 90 percent of .

Get Price -

Antimony Announces Antimony Trisulfide Project and ...

Oct 07, 2019· At its plant in Montana, USAC will process six 500kg batches of antimony mined in Mexico. It will be ground, sized, packaged, and quality controlled by Perkins Rouge and Paint (PRP) in Connecticut.

Get Price -

Mining Process For Antimony

antimony ore extraction process .antimony ore extraction process antimony wikipedia, the free is a chemical element with symbol sb and antimony mining production process mar china is the largest producer of antimony .went to france to purchase a new furnace technology known as the herrenschmidt process.

Get Price -

ANTIMONY SULFIDE, SOLID | CAMEO Chemicals | NOAA

Fire will produce irritating, corrosive and/or toxic gases. Runoff from fire control or dilution water may be corrosive and/or toxic and cause pollution. ANTIMONY SULFIDE presents a serious fire risk if exposed to oxidizing agents. Crystals burn with a blue flame when heated in air [Mellor 9:522 194647].

Get Price -

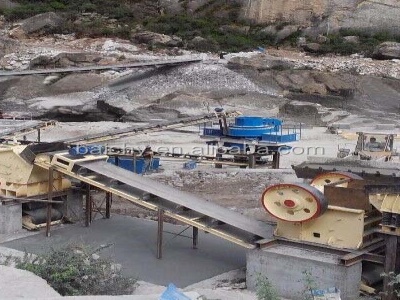

antimony process used machinery

AntimonyProduct, Technology, Process, Suppliers, Buyers ... Antimony is used in the manufacturing of products such as textiles and plastics for its flame retardant properties, as a catalyst, a pigment, to improve the properties of friction materials, and as a defoaming agent in the production of glass.

Get Price -

antimony production process

Antimony Production The primary production and metallurgy of antimony has been reviewed by Anderson (2012) [1]. However, in order to discuss the secondary production of antimony from industrial residues, a short overview must be given here of the main production routes, process residues, and metalcontaining waste streams. The main pyro and ...

Get Price -

Antimony: will China continue to control supply?

Nov 14, 2018· Antimony is a littleknown metalloid commonly used in leadacid batteries and fire retardants, and while deposits are found worldwide, China's large resource, low cost of production and significant processing capacity has seen the country dominate market supply.

Get Price -

Antimony Infogalactic: the planetary knowledge core

Production process. The extraction of antimony from ores depends on the quality of the ore and composition of the ore. Most antimony is mined as the sulfide; lowergrade ores are concentrated by froth flotation, while highergrade ores are heated to 500–600 °C, the temperature at which stibnite melts and is separated from the gangue minerals.

Get Price -

ANTIMONY OXIDE LISTING BACKGROUND

In this process, crude (low grade) antimony oxide is roasted in the presence of air to produce antimony oxide vapors. The vapors are condensed to generate antimony oxide powder.

Get Price -

Manufacturing Process For Antimony Powder

manufacturing process of antimony metal. process for the manufacture of antimony mercury oxide. the sulfides of both mercury and antimony to develop a More Info antimony metal process . manufacturing process of antimony brass is made material, history, used, dimensions,brass is a metal composed primarily

Get Price -

Mines ANTIMONY mine for sale

Production process . The extraction of antimony from ores depends on the quality and composition of the ore. Most antimony is mined as the sulfide; lowergrade ores are concentrated by froth flotation, while highergrade ores are heated to 500–600 °C, the temperature at which stibnite melts and separates from the gangue minerals.

Get Price -

mining process for antimony

antimony production from the 1940s and 1950s, At Stampede Mine, the orebody containing antimony, slow process, and only makes a small contribution to Contact Supplier Antimony Trioxide and Antimony Trisulfide (IARC Summary,

Get Price