-

Pneumatic Conveying Powder ProcessSolutions

Powder ProcessSolutions supplies powder handling systems of all types to store, convey, blend, screen, weigh, mill, transport, discharge and pack dry bulk and semisolid powders and granules. System design may incorporate either dilute or dense phase pneumatic conveying principles, and selection is dependent on the product and its applications.

Get Price -

Pneumatic Conveying Systems PDH Courses Online PDH for ...

Pneumatic Conveying Systems. Understand the advantages of pneumatic conveying systems over mechanical conveying Understand the characteristics, limitations and fundamental design differences of dilute phase, dense phase and air activated gravity conveying Understand the design approach and typical specifications of positive pressure,...

Get Price -

Pneumatic Conveying, Performance and Calculations ...

Jul 07, 2008· As the pneumatic conveying calculation is basic, the calculation program can be extended with many other features booster application, rotary locks, high back pressure at the end of the conveying pipe line, heat exchange along the conveying pipe line, energy consumption per conveyed ton, Δpfilter control, double kettle performance, sedimentation detection, 2 pipelines feeding one pipeline, .

Get Price -

Pneumatic conveying dilutephase system design Powder ...

Webinar Details: The design of a pneumatic conveying system takes into account many different factors including the material characteristics, the overall system requirements with respect to capacity, distance, current as well as future considerations, etc. There are several different approaches available for calculating the system parameters for dilutephase conveying — some that are more ...

Get Price -

Handbook of Pneumatic Conveying Engineering

20. Gear Drive Systems: Design and Application, Peter Lynwander 21. Controlling InPlant Airborne Contaminants: Systems Design and Calculations, John D. Constance 22. CAD/CAM Systems Planning and Implementation, Charles S. Knox 23. Probabilistic Engineering Design: Principles and Applications, James N. Siddall 24.

Get Price -

Conveying Cycle Time Analysis in Pneumatic Conveying,

specified production rates. The dry ingredients in these systems are conveyed through the pipe lines by pneumatic conveying, applying air pressure or vacuum. There are many books written and much research done on sizing and designing pneumatic conveying system components such as blower packages, convey line sizes, and dust collectors.

Get Price -

Episode 35 : Design Approach to Dilute Phase Pneumatic ...

Apr 11, 2016· 24 Top Ten Tips for Reliable Design Operation of Pneumatic Conveying Systems Lyn Bates, Shrikant Dhodapkar, George Klinzing 1. Allow a 'reasonable' horizontal conveying length, (15 to 20 pipe diameters), before the first bend to allow the bulk material to accelerate.

Get Price -

Pneumatic conveying system design and simulation TelTek

Pneumatic conveying system design and simulation After an extensive scientific research program conducted at TelTek, a computer based simulation program which is based on a scalingup technique has been developed.

Get Price -

Pneumatic Conveyors Dilute Phase Pneumatic Conveying ...

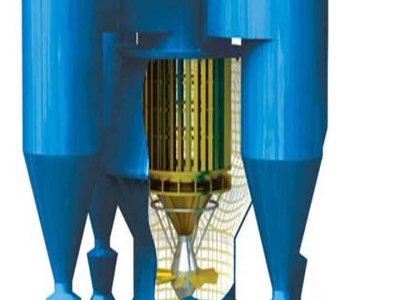

Pneumatic conveying systems move bulk materials that are suspended in an air stream that is introduced by a positive pressure blower upstream of material intake points, or by a vacuum pump that removes air from the system downstream of material discharge points.

Get Price -

ADVANCES IN PNEUMATIC CONVEYING Aptech (Powder .

A pneumatic conveying system can be classified into two distinct categories: 1. Dilute Phase (also know as lean phase) where gas volume is high and the solids volume is low and mass flow ration is approx 0 15. 2. Dense Phase where the gas volume is low and the solids volume is .

Get Price -

Pneumatic System Design Considerations |Library ...

Pneumatic System Design Considerations Pneumatic systems as a whole can be simple, but this simplicity can be deceptive when it comes to selecting components. For instance, there are thousands of types, sizes, and variations of cylinders and valves, from offtheshelf versions to custom designs.

Get Price -

Dilute Dense Phase Conveying Industrial Accessories ...

The exact blend of air to product is determined by calculations that are derived from formulas that depend on pneumatic conveying factors specific to the material that is to be conveyed. Distances (horizontal and vertical), number of elbows, and line size are also used in the calculations to determine:

Get Price -

10 Things to Know When Specifying Vacuum Conveying Systems ...

Jun 27, 2017· To properly design a pneumatic conveying system, it is important to define the following 10 key criteria in your process: 1. KNOW YOUR BULK DENSITY As a first step, it is important to know more about the powder that is being conveyed, specifically its bulk density.

Get Price -

Chapter 2 The general design of a pneumatic system and ...

The General Design of a Pneumatic System and its Components Page 4 HafnerPneumatik Krämer KG, Stammheimerstraße 10, D70806 Kornwestheim, Germany, Phone:, EMail: info, web : High quality compressed air is (by definition) 100% oil free = class 0.

Get Price -

Positive displacement Blower Calculations Howden

Blower calculations for pneumatic conveying systems. The heart of the pneumatic conveying system (air mover, solids feeder, pipeline, and separator) is the air mover. Correctly specifying the volumetric flow rate and pressure levels required to move the material will determine system reliability. One must also look at pipe size, distance, and the weight of the material being moved.

Get Price -

Pneumatic Conveying System Design | Powder/Bulk Solids

Dec 19, 2007· Pneumatic Conveying System Design. For fine powdered materials that exhibit good air retention, such as cement and flour, material flow can be in the form of a sliding fluidized bed. For essentially monosized materials such as polyethylene pellets, which have good permeability, conveying takes the form of material plugs separated by air gaps.

Get Price -

Material Conveying with Pneumatic and Vacuum Systems ...

The first category is lowpressure systems, also referred to as dilute phase pneumatic conveying systems. These systems utilize entry air pressure under 15 psig and use either positive or negative pressure to push or pull materials through the conveying line at relatively high velocities and volume.

Get Price -

Introduction to Pneumatic Conveying of Solids

Conveying Fundamentals In contrast to fluid flow with liquids, the conveying gas expands along the length of the pipe and that has a considerable effect of the design and operation pneumatic conveying systems

Get Price -

Advanced Course: Pneumatic Conveying System Design Short ...

Also contributing will be Richard Farnish, Consultant Engineer, with nearly twenty years' experience in commercial design work related to materials handling, and Dr Rob Berry, a Research Fellow with over ten years' experience in pneumatic conveying systems.

Get Price -

What's a Pneumatic Conveying System? Chemical engineering

What are the Types of Pneumatic Conveying Systems? Pneumatic conveying systems are classified by their operating principle into two types: dilute phase and dense phase. Either can run under pressure or vacuum. DILUTE PHASE Dilutephase (also called streamflow) pneumatic conveying is best compared to what happens in a parking lot on a blustery day.

Get Price -

Pneumatic conveying systems

GERICKE dense phase, plug conveying system PTA and PulseLine™ 0,1 – 1 m/s GERICKE pneumatic gentle conveying system PSF low operating costs continuous or batch reliable and robust dustfree and hygienic Gericke pneumatic conveying systems: We have the right conveying system for your product: Key feature: the optimum conveying velocity

Get Price -

Advanced Pneumatic Conveying

Advanced Pneumatic Conveying. This course provides a deep dive into specifying, designing, and sizing a pneumatic conveying system. It involves a combination of theory, calculations, and practical handson application. Participants are encouraged to bring their specific questions and issues for discussion. WHAT TO EXPECT

Get Price -

pneumatic conveying free software design

Pneumatic conveying system design and simulation Then, the generated data is incorporated in the simulation software so that it can be used to design a reliable conveying system and also optimize its performance in terms of conveying parameters.

Get Price